It is the initial step in the splicing process. Last primer coating process. Hardwood flooring manufacturing process.

Hardwood Flooring Manufacturing Process, Removing irregular edges and defects from sawn pieces. At this point the engineered flooring process briefly resembles the milling of solid hardwood flooring. Other areas of use for MDF include doors interior trim applications in the automotive industry the construction industry or in semiconductor manufacturing. The directory which contains over 800 machine types was compiled by the European association EUMABOIS and is under continuous development.

What Is Engineered Wood Flooring Made Of Wood And Beyond Blog From woodandbeyond.com

What Is Engineered Wood Flooring Made Of Wood And Beyond Blog From woodandbeyond.com

When the finish wears out though refinishing options vary. We offer top grade European French White Oak American Walnut and Northern Canadian Maple hardwood flooring in both Engineered and Solid wood planks in variety of contemporary and modern custom finishes for both residential and commericial markets. The manufacturing processes of hardwood flooring are fellow the flowing basic steps. This style of flooring also uses lamination.

The veneer is then pressed flat with high pressure.

Read another article:

By gluing the wider surfaces together facing up horizontal bamboo flooring is created. MDF is mainly used in the furniture and flooring industry as well as in interior design. Stack up raw timber after Inspection. Base primer spraying on back side. At this point the engineered flooring process briefly resembles the milling of solid hardwood flooring.

Source: lifewood.com.au

Source: lifewood.com.au

What might not be as easily understood are the processes involved in taking that timber and turning it into planks that eventually adorn your living room kitchen bedroom etc. Six sides primer coating application by machine. A similar clipping or cutting process is performed to acquire sheets of a proper width. In this directory you will find machines for each operation in primary and secondary wood processing. What S The Difference Between Solid And Engineered Timber Flooring.

Source: woodandbeyond.com

Source: woodandbeyond.com

The boards can be veneered laminated painted or otherwise coated. This video show songlin factory overview and engineered hardwood floor manufacture process. The plywood underneath the real hardwood veneer is referred to as the core board. Six sides primer coating application by machine. What Is Engineered Wood Flooring Made Of Wood And Beyond Blog.

Source: rippnfinish.com

Source: rippnfinish.com

LM Flooring has over 150 styles of wood flooring and veteran artisans expertly craft each one. This video show songlin factory overview and engineered hardwood floor manufacture process. LM uses both domestic and exotic wood species to create a wide range of hardwood flooring. The manufacturing processes of hardwood flooring are fellow the flowing basic steps. Can You Refurbish Pre Finished Hardwood Flooring Hardwood Floor Refinishing.

Source: indojatiutama.com

Source: indojatiutama.com

The quality of the veneer panel depends on the precision and angle of the cut. The laminating process makes the thickness of the flooring uniform throughout. Base primer spraying on back side. The quality of the veneer panel depends on the precision and angle of the cut. Merbau Wood Flooring And Decking Solid Wood Flooring Company Indonesia.

Source: builddirect.com

Source: builddirect.com

The quality of the veneer panel depends on the precision and angle of the cut. It is the initial step in the splicing process. When the finish wears out though refinishing options vary. Other areas of use for MDF include doors interior trim applications in the automotive industry the construction industry or in semiconductor manufacturing. How Is Hardwood Flooring Is Made Builddirect Learning Centerlearning Center.

Source: architecturaldigest.com

Source: architecturaldigest.com

Then at the sawmill the first thing need to di is bucking the hardwood to length. Machine and Equipment for Flooring Production Many consumers are aware that the wood for a solid hardwood engineered wood floor comes from a tree obviously. After preparation the wood is peeled by a blade starting from the outside of the log and working toward the center thus creating a wood veneer. Manufactured and solid wood floors typically have similar finishes that last for 20 years or more and they require similar maintenance. How To Choose Install Hardwood Floors A Complete Guide Architectural Digest.

Source: hoskinghardwood.com

Source: hoskinghardwood.com

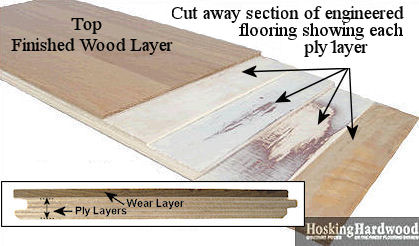

Then at the sawmill the first thing need to di is bucking the hardwood to length. Engineered wood flooring is constructed by gluing together a number of wood plies with a veneer of real hardwood veneer glued on top. Six sides primer coating application by machine. Manufactured and solid wood floors typically have similar finishes that last for 20 years or more and they require similar maintenance. All About Floating Wood Floors.

Source: youtube.com

Source: youtube.com

The boards can be veneered laminated painted or otherwise coated. The boards can be veneered laminated painted or otherwise coated. Solid Timber Floor Manufacturing. This process involves treating the wood by boiling the log in water. Unilin Production Process Parquet Youtube.

Source: builddirect.com

Source: builddirect.com

Synfonia Floors is a lead manufacturer of high quality designer and custom hardwood floors. The manufacturing process begins with the rotary-peeling of logs into veneer about 3 mm 0125 in thick. Six sides primer coating application by machine. This video show songlin factory overview and engineered hardwood floor manufacture process. How Is Hardwood Flooring Is Made Builddirect Learning Centerlearning Center.

Source: oldewoodltd.com

Source: oldewoodltd.com

See also various other 11 Stylish Hardwood Flooring Manufacturing Process below here. This video show songlin factory overview and engineered hardwood floor manufacture process. After preparation the wood is peeled by a blade starting from the outside of the log and working toward the center thus creating a wood veneer. The plywood underneath the real hardwood veneer is referred to as the core board. How To Acclimate Plank Floors Before Installing.

Source: info.floordecorct.com

Source: info.floordecorct.com

The veneer is then pressed flat with high pressure. What might not be as easily understood are the processes involved in taking that timber and turning it into planks that eventually adorn your living room kitchen bedroom etc. Removing irregular edges and defects from sawn pieces. The boards can be veneered laminated painted or otherwise coated. Pre Finished Vs Site Finished Hardwood Which Is Better.

Source: uptownfloors.com

Source: uptownfloors.com

Engineered wood flooring is constructed by gluing together a number of wood plies with a veneer of real hardwood veneer glued on top. Machine and Equipment for Flooring Production Many consumers are aware that the wood for a solid hardwood engineered wood floor comes from a tree obviously. Other areas of use for MDF include doors interior trim applications in the automotive industry the construction industry or in semiconductor manufacturing. They are cut with clipper to obtain sheets that are even in length. 3 4 Inch Thick Engineered Hardwood Flooring 5 8 Mm Wear Layer.

Source: simplefloorspdx.com

Source: simplefloorspdx.com

The plywood underneath the real hardwood veneer is referred to as the core board. MDF is mainly used in the furniture and flooring industry as well as in interior design. This process involves treating the wood by boiling the log in water. This video show songlin factory overview and engineered hardwood floor manufacture process. How Wood Floors Are Made.

Source: blog.cityfloorsupply.com

Source: blog.cityfloorsupply.com

The manufacturing process begins with the rotary-peeling of logs into veneer about 3 mm 0125 in thick. The veneer is then pressed flat with high pressure. The quality of the veneer panel depends on the precision and angle of the cut. The boards can be veneered laminated painted or otherwise coated. Which Tools Do You Need To Install Engineered Hardwood Floors City Floor Supply Blog.

Source: builddirect.com

Source: builddirect.com

The veneer is then pressed flat with high pressure. After preparation the wood is peeled by a blade starting from the outside of the log and working toward the center thus creating a wood veneer. LM uses both domestic and exotic wood species to create a wide range of hardwood flooring. The laminating process makes the thickness of the flooring uniform throughout. The Evolution Of Engineered Hardwood Flooring Builddirect Learning Centerlearning Center.